EnBW and Spelsberg are developing charging stations

Partner for the mobility of tomorrow

- EnBW is the third largest energy company in Germany

- With EnBW mobility+, EnBW customers have access to the largest charging network in Germany, Austria and Switzerland

- Development of an intelligent street lamp with charging function with the EnBW start-up SMIGHT

- Development of a unique charging station including public grid connection

- Partnership working from the prototype to the series

The company

EnBW Energie Baden-Württemberg AG, the third largest energy company in Germany, is working together with its corporate startup SMIGHT on the development of individually designed and technically sophisticated charging stations. The company relies on Spelsberg's technical know-how and many years of experience. In close cooperation, they are setting new standards for clean, electric mobility.

With a view to urban infrastructures, the term Smart City inevitably comes into focus. As a charging infrastructure operator, EnBW has set up the largest fast charging network in Germany and continues to expand it. At the same time, as the best and largest e-mobility provider in Germany, EnBW enables easy charging at more than 100,000 charging points in Germany, Austria, Switzerland, France, Italy and the Netherlands at the same price everywhere.

"It was outstanding how individually adaptable the specific products at Spelsberg are, and how flexible the response was to our special requirements for the system."

Marco Masur, Product Manager EnBW AG

The project in detail

More than just vision

The SMIGHT innovation project underlines the importance of topics such as e-mobility in the realignment of the company as an infrastructure service provider.

For more than five years, the team at the corporate startup has been working on the vision of digitally networked cities and is designing hardware and software-based IoT solutions. In addition to integrating its own technologies into existing infrastructures, EnBW is focusing on the in-house development of entire charging stations with SMIGHT, which stand out from the existing market through function and design.

To do this, the project developers placed high demands on the properties of the columns right from the start: "It was particularly important to us to offer a product that impresses with its quality, reliable operation and durability and that also enables more than existing solutions on the market," says Marco Masur, product manager at EnBW. As a young start-up in a new business area, SMIGHT was dependent on partners with a wide range of skills that Spelsberg was able to demonstrate through its many years of experience as a specialist in enclosures.

Individual and flexible

The joint implementation was born out of the idea of bringing our own charging station onto the market. Spelsberg had already been involved in the process of constructing a number of prototypes and designed possible developments of the later system together with EnBW and SMIGHT

Based on a master draft, Spelsberg planned the assembly of all components in a single enclosure. In addition to the technical implementation and the delivery of components, Spelsberg was able to guarantee a smooth process, especially in the area of compliance with all standards and regulations.

In-house test laboratory

In the in-house, certified test laboratory, Spelsberg ensures the functionality of its products and the applicable standards according to VDE and UL. "In the field of e-mobility, it is important to comply with a large number of standards and rules under the calibration regulations. We had to be sure that we were developing a product that fully meets these specifications. Here, too, Spelsberg supported us in a goal-oriented manner", says Marco Masur.

Know-how from Spelsberg

Spelsberg offers its customers a wide range of services and products for the manufacture of housings and their assembly - all under one roof. The cooperation between SMIGHT and Spelsberg started in an early phase of the innovation project and was then continuously built upon: "In the field of grid connection technology, EnBW had been dealing with Spelsberg for a long time. We were able to further expand the close and partnership-based business relationship in developing the new business model," explains Oliver Deuschle, Managing Director at SMIGHT

Solution-oriented into the future

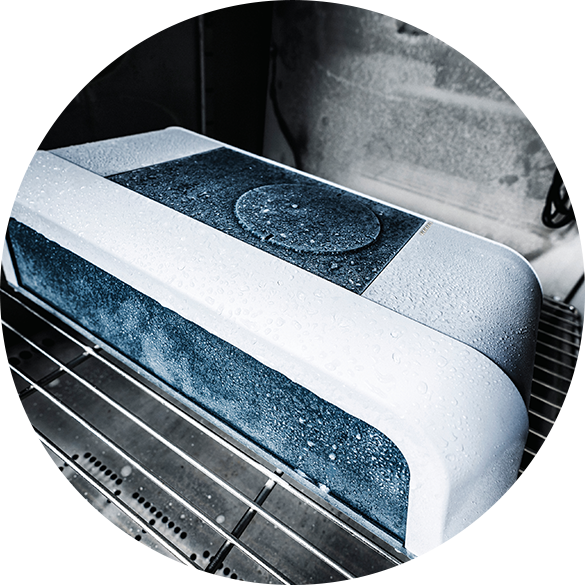

Today, e-car drivers in public spaces benefit from unique charging stations that are both visually and technically impressive - and second generation is already here. Even in the initial version, two connections per charging point represented a novelty on the market. The new generation also ensures barrier-free access in accordance with DIN 18040-3 thanks to its underride capability of up to 15 cm. Maintenance work and the replacement of components can also be carried out effortlessly. The charging stations are subject to continuous further development in order to be able to survive in the market. EnBW will continue to work in partnership with Spelsberg.

"In Spelsberg we have found the best possible sparring partner for us, so that we can continue to provide the absolute best for the customer. Both sides can play to their strengths here – us by listening to the market and customers, and Spelsberg with their development and product skills."

Oliver Deuschle, Managing Director at SMIGHT

Tested, certified and tailor-made

With 5,000 sockets, distributors and housings, Spelsberg offers high-quality products from an extensive catalogue as well as options for individual customizing with different degrees of added value. Due to the immense vertical range of manufacture, from development to toolmaking and production to testing in our own laboratory, we can process and implement individual customer requests particularly quickly and flexibly.

The flawless functionality of the products is tested and confirmed in our in-house, certified test laboratory. Here we not only test according to VDE, but also according to UL standards, which are important in the global market. Our international standards experts review products early in the design phase to ensure that all requirements are met.

We are also your competent partner for device assembly and product selection within the enclosure . We will help you to select the right components and take care of the assembly and final testing, including the necessary certificates.

The load and resistance of the products to extreme temperatures, climates, water and dust as well as their impact strength and resistance to fire are tested in our modern test facilities. Annual audits of all testing systems and staff ensure that the laboratory is certified and that the products are tested in accordance with standards.

We provide many years of experience and associated in-house competence, for your benefit.

More success stories from our customers